Production Standards are a set of rules and guidelines that ensure consistency and quality in the design and delivery of production or services.

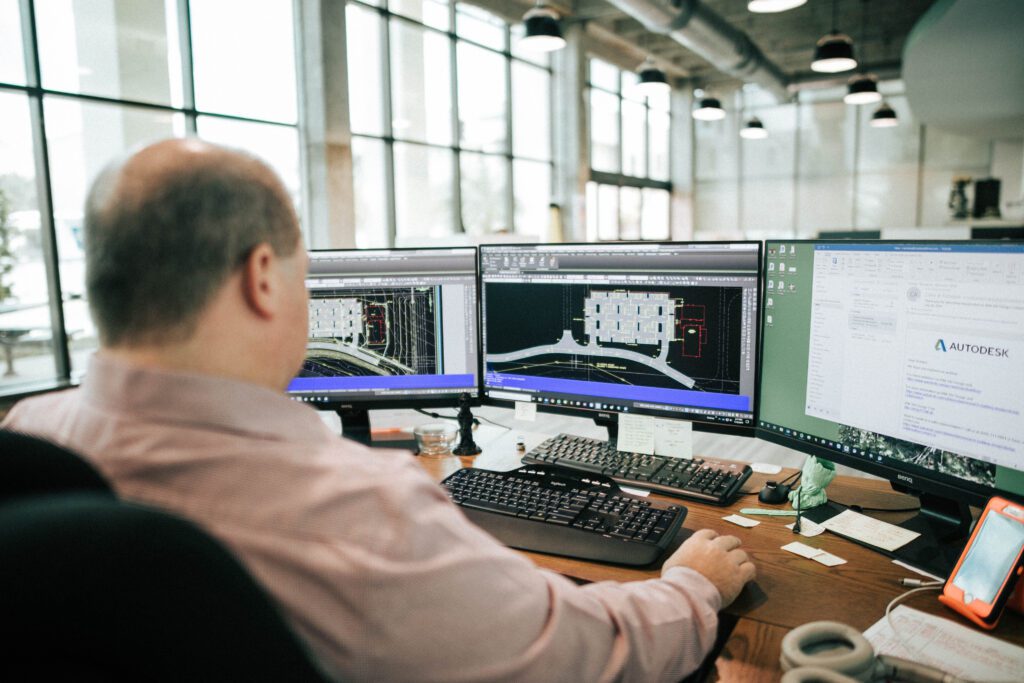

In CAD design, Production Standards include things like templates, styles, settings, naming conventions, file management, drawing organization, and dimensioning. These standards help designers create drawings that look professional, follow best practices, and meet the client’s expectations.

What are the Benefits of Establishing Production Standards?

Production Standards are important because they provide every user with the tools they need to design projects proficiently. Some benefits of establishing Production Standards include:

- Time-Saving Templates: Establishing Production Standards guarantees users will have templates to use with the tools needed for each task pre-saved. Rather than creating new styles and changing settings for every drawing worked on, these templates mitigate the need to recreate the wheel for each new project.

- Improved Cross-Utilization: Production standards ensure that if the project gets handed off to another designer, that designer can pick up right where the first designer left off. There is no figuring out what style they used for this or that. When the tools to do a job and the supplies are the same, the outcome should be the same. This helps tremendously when we start talking about cross-utilization between company departments. If companies are not strictly enforcing Production Standards, there will be a lot of wasted time and effort.

- Enhanced Onboarding and Training Initiatives: Having CAD Production Standards also makes it easier to train and onboard new designers. They can quickly learn the company’s expectations and procedures for CAD design by following the Standards Manual and using the templates. This reduces the learning curve and the need for supervision or correction. It also ensures that the new staff members can produce drawings that are consistent with the company’s brand and quality.

Developing Production Standards: It Takes a Team!

At Chastain-Skillman, our team members work to establish Production Standards that are as clear, concise, and consistent as the drawings we produce. Our project directory structure is set up for success with file naming conventions for saving drawings and other related documents. Our templates are continually being updated as we adapt to emerging technology and software.

Communication is key, and our team members make sure to inform CAD Managers of any styles and settings that need to be added to the templates. Production Standards are ever-changing and no one person can capture everything in a template without the help of good staff.

Adapting Production Standards to New Technology

So, you’ve managed to create a set of Production Standards and your team has fully adopted it. Now what? Well, it should come as no surprise that technology is constantly evolving, and along with it comes the necessary evolution of existing practices (and in this case, your Production Standards!).

Production Standards should be updated as often as software and new tools are developed. However, it takes more than a CAD Manager to implement the new changes. A design team, management, and team members alike, can play a huge role in streamlining updates to the firm’s Production Standards by making note of new tools or methods used to work on projects. These observations can then be communicated to management and subsequently added to the CAD Standards Manual to improve workflows and make projects easier and/or more expedient, which helps to meet deadlines.

In Conclusion

Production Standards are essential for achieving consistency and quality in CAD design and deliverables. By establishing a framework for how designs are completed, Production Standards save time, eliminate guesswork, improve cross-utilization, and enhance onboarding and training initiatives. These benefits not only increase the efficiency and productivity of the design team but also the satisfaction and trust of the clients and stakeholders. Chastain-Skillman’s Production Standards directly reflect both the firm’s brand and reputation in the competitive A/E/C industry. Therefore, it is important for our team to develop, update, and follow Production Standards that adapt to new technology and software. As we have seen, Production Standards are not just a set of rules and guidelines, but a way of ensuring excellence and innovation in CAD design.

Interested in services? Give us a shout! ↓

Share Article

About the Author

Richard Carnahan has over 23 years of experience specializing in producing CAD drawings for the construction of roadways, developing preliminary layouts, and preparing construction drawings. His professional experience includes preparing CAD drawings for the construction of roadways, subdivisions, and commercial properties; developing preliminary layouts and preparing construction drawings for roadway design projects; preparing FDOT-funded roadway plans, signing and pavement marking plans, and MOT plans; preparing water distribution and wastewater collection system linear utility plans; preparing plans for stormwater collection and treatment facilities; and creating GIS exhibit maps for Water Management District permit submittals.

About Chastain-Skillman

CS is a leading engineering firm headquartered in Lakeland, FL, with satellite offices in Orlando, FL, and Nashville, TN. Established in Lakeland in 1950, our company provides Civil Engineering, Water/Wastewater Engineering, Land Surveying, Geology/Hydrogeology, and Construction Management/Inspection services.

At CS, we treasure our role in creating thriving communities, always respecting the impact our work has on their foundations and their futures. For more information, visit chastainskillman.com.